Drug Plastics has been manufacturing plastic bottles and closures for over 60 years. But we’re not just a manufacturer. Did you know that we also custom design beautiful plastic packaging that will differentiate your products from other brands?

That’s right! We have talented people, cutting-edge tools, and decades of experience designing packaging for dozens of pharmaceutical, healthcare, and nutrition companies.

That’s right! We have talented people, cutting-edge tools, and decades of experience designing packaging for dozens of pharmaceutical, healthcare, and nutrition companies.

When you require a custom design for your packaging, don’t contract with an outside packaging consultant.

Work with us instead and create a design that incorporates all the attributes your packaging needs – from dimensional integrity, and the proper resin for your product – to selecting the best manufacturing process, and the peace-of-mind that comes with our repeatable quality, our team of experts can help you make the right choice. We will take your project from concept to completion – all in-house – with our on-staff design engineers. Here’s what we offer.

Talented Design Engineers on Staff

Our knowledgeable team thinks outside the box and works with you to understand how your packaging should look, how it should function, the specifications it must meet, and your budget requirements. We design innovative components that work together, ensuring a complete package that distinguishes your brand and saves you money.

Too often we have seen designers model distinctive packages that can’t be molded or don’t run efficiently in a factory production setting, leading to unnecessary costs and piece price charges. Design consultants just don’t have the experience in manufacturing and adherence to specifications to produce a package that is beautiful and runs efficiently at a reasonable cost.

Many years of design and manufacturing experience helps our customers bring their packaging goals to life from start to finish. Our engineers know the manufacturing equipment inside our plants – what runs well and what doesn’t; what resins are best for specific products; and what manufacturing process is best for the finished bottle and closure.

Cutting Edge Software and Equipment

During the design phase, our team utilizes 3D printer technology that can help identify proper fit and function between components. This equipment is also used to make small quantities of bottle and closure models in various colors. The models can be ordered to help the customer visualize the final product*.

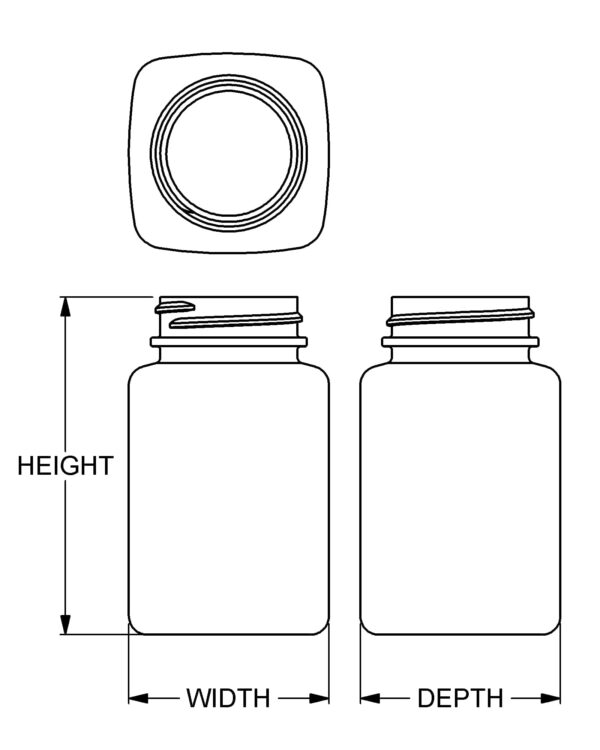

Once a design is selected, a detailed CAD product drawing is created, outlining every critical dimension of the bottle or plastic closure. This drawing provides the direction needed to create manufacturing molds, and is used as a reference check to ensure that the product we make meets the exact specifications.

Mold Manufacturing

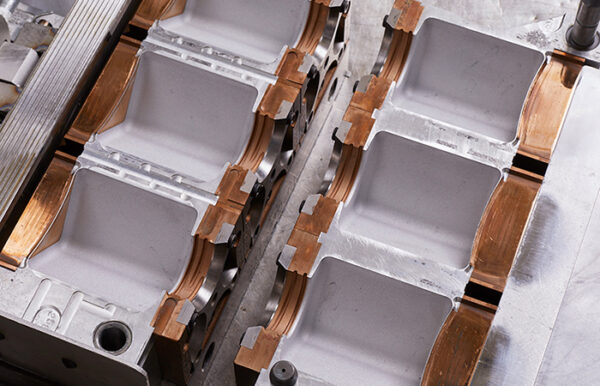

We have our own mold-making facility, where we design, fabricate, qualify, maintain, and repair our molds. We build precision tools using high-grade materials and proprietary technologies we developed in-house.

We have our own mold-making facility, where we design, fabricate, qualify, maintain, and repair our molds. We build precision tools using high-grade materials and proprietary technologies we developed in-house.

This ensures that our molds produce a consistent product, perform exceedingly well on our manufacturing equipment, and perform under high production demands. This results in a higher ROI for your custom packaging.

Design and Manufacture with Us

At Drug Plastics, we know that custom bottles and closures have to be unique and made specifically for a product. We also know that there may be several ways to achieve the desired look, while meeting the strict specifications a product requires. Once the best design option is selected, we can guide you on:

Resin Selection: each resin has distinct properties that may or may not work with specific product types. We help you determine which resin is the right choice for your product.

Color Selection: we have color options to meet your brand requirements. We have standard colors, but we can also match a specific PMS color if your brand requires it.

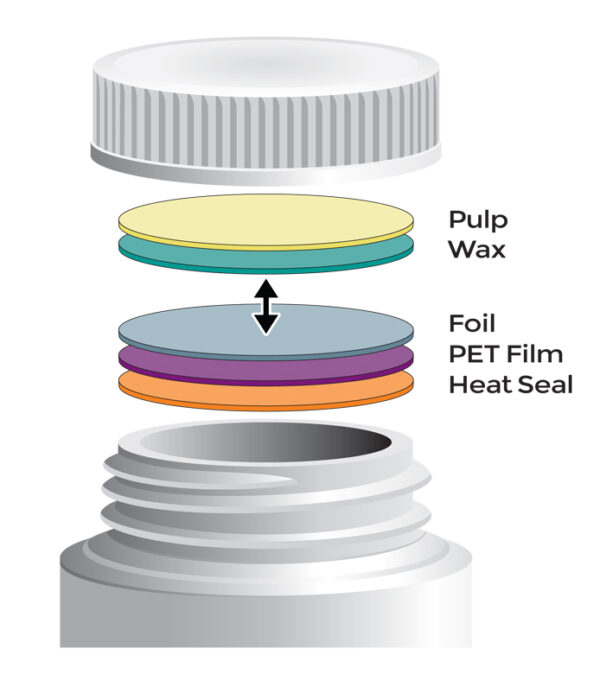

Closure Liner Selection: certain closure liners are designed to work with liquids, and others are designed to work with solid dose products. The correct liner protects your product as well as the consumer, and it can also save you money.

Manufacturing Process Selection: several different manufacturing processes are available. The size and geometry of the bottle and the resin type being used are the big factors that determine how we produce our products. Our team will guide you in selecting the right process. Can a design consultant help you with all these technical decisions?

Experience

For over six decades, Drug Plastics has been designing and manufacturing custom packaging for many pharmaceutical, healthcare, and nutrition products. Unlike design consultants, we understand the packaging needs and challenges facing these industries. This knowledge allows us to service producers of prescription drugs, self-care medications, and vitamins and supplements better than anyone else. Our team stays up-to-date on the ever-changing regulations and requirements that these industries face daily.

A One-Stop-Shop

Custom bottles and closures are a great way to differentiate your products and market your brand to consumers. We’re not just a plastic packaging manufacturer. Drug Plastics can design eye-catching bottles and closures for your products, on-time and on-budget, without the additional cost incurred by using a packaging  consultant.

consultant.

No need to worry about costly design re-work at the manufacturer: we are the manufacturer. We will never design a bottle or closure that we can’t make in our manufacturing facilities.

Ready to tackle your custom packaging design? Call 610-367-5000 to speak with someone immediately.

*Please note: the material used to make sample molds from the 3D printer is not the same material used to make the final bottle and closure products during production.